Tophill being one of the best PCD Pharma franchise companies in India recognizes the importance of managing EHS (Environment, health &safety) in workplace. For creating a safe and healthy environment in the workplace, tophill is taking some practicable measures for its employees.

Keep the environment clean and workplace safe

At Tophill, our goal is to be a leader in Environment, Safety and health. We are fully committed to achieve excellence in EHS. We try our best to manage and implement EHS to our workplace in a responsible way. The importance of EHS is continually stressed and extensively promoted as a part of our corporate culture.

Awareness on hygiene

When it comes to the workplace, cleanliness and personal hygiene is the most important thing as they are always included in every company’s norms and policies. Necessary training is imparted to employees to enhance their awareness in health and safety related matters.

Our Duty

Businesses are there to grow and make profits. But it should never be at the cost of the environment and the safety of the employees. When we started out, it was with the sole objective of making life better. Nothing much has changed now. We want to make sure that lives we touch get better, which includes not just our consumers, but our employees and the environment we work in. It's our duty.

EHS Policy

For the overall health and safety of our employees and the environment, we have put in place an Environmental Health and Safety Policy (EHS Policy). And we are highly strict about it.

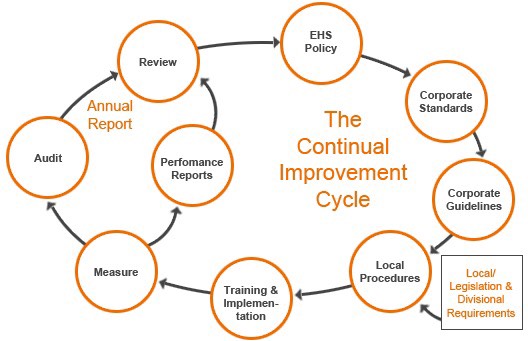

Let us decode it for you

EHS policy is a step by step process towards responsible manufacturing practices that takes meticulous study, preparation and then acting on it. It also involves putting various systems in place to make operations safe for the employees and the environment. Here they are.

Setting a Goal

To begin with, EHS policy includes establishing standard documented procedures and guidelines and setting up of corporate EHS goals.

Assessing potential risk

Then comes identifying workplace and environmental hazards through organisational risk assessment process.

Time to act

After identifying the risks, the next logical step is implementation of necessary control measure.

Not just corrective

And not just corrective, EHS also involves taking preventive measure. It means accounting for EHS in key business decisions such as plant layout, equipment, manufacturing and distributing process.

Check on carbon footprint

All equipment’s and machineries has to pass through rigorous quality checks including carbon emission test. Only those machines make it to our factory that minimises carbon footprint and maximises productivity.

Recycling

A lot of natural resources are used in the process of manufacturing. By recycling water, fuel and energy and by reducing waste from it we try to give it back to the environment.

In and around

And not just inside the units, we promote greening of the environment by planting trees around our units.

Better ways of operation

Besides adopting new technologies to make our work-place safer for the employees and the environment, we are engaged in continuous research and development to introduce new and better ways of operation.

Back to school

Safety of our people is our top priority. For this, we conduct training and awareness classes for our employees and contractual workers on a regular basis.

Keeping a record

Accidents do happen. The idea is to prevent it from happening again. For that, we document such cases, if any, the conduct thorough investigation to its cause and promptly adopt measure so that it's never repeated again. It helps us reach our goal of zero accident.

Keeping a tab

Our responsibility doesn't end in adopting EHS measure. We review them periodically to check compliances, to ensure that it remains relevant and appropriate for the organization

Basic Virtuous Circle of EHS Management System